Kakuhunter’s Mixing Mechanism

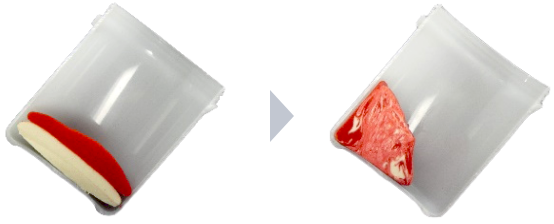

The planetary centrifugal mixer ”Kakuhunter” mixes and disperses uniformly while simultaneously defoaming.

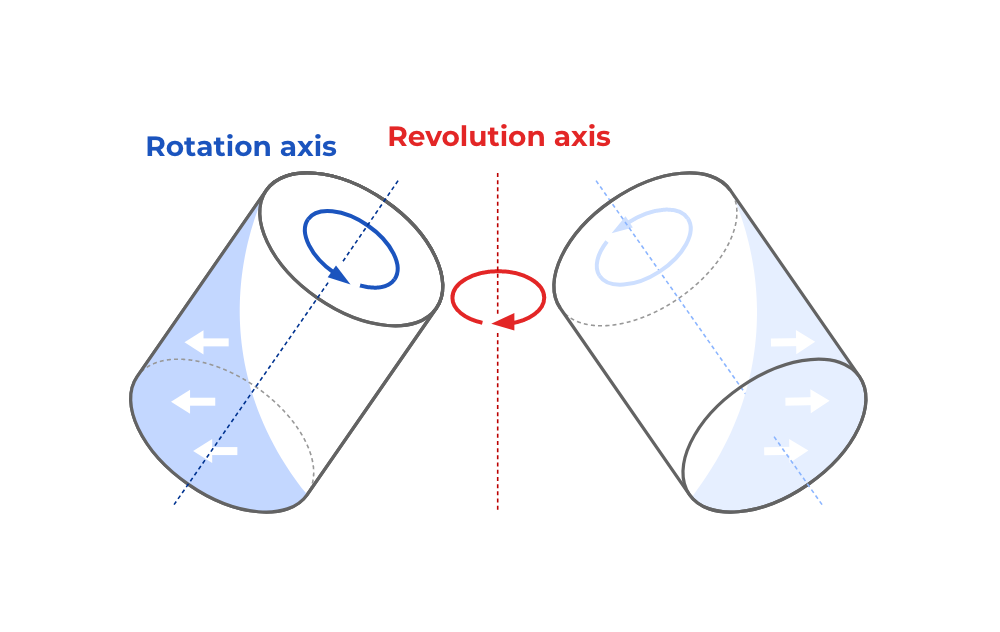

Principles of Mixing and Defoaming

- The containers revolve

- Rotation starts simultaneously

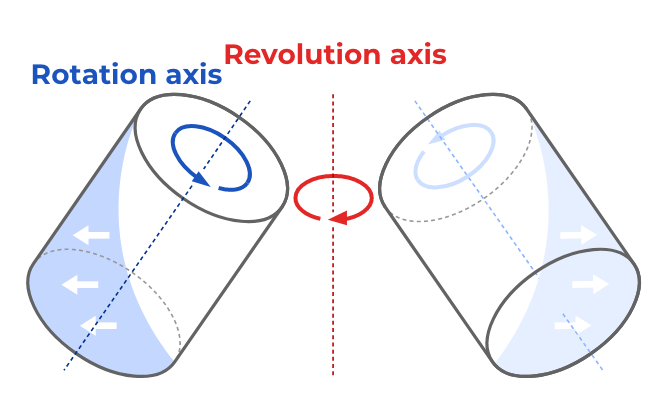

- Vortex and up-and-down flows are generated and mixing proceeds

- Defoaming is performed as bubbles are separated and broken

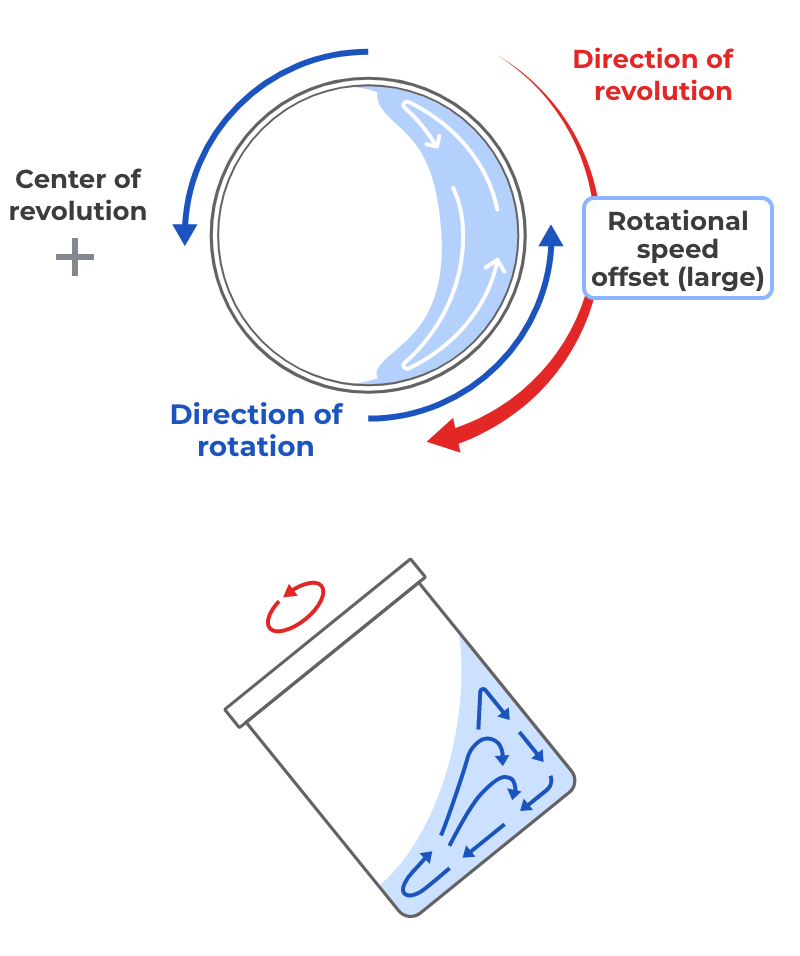

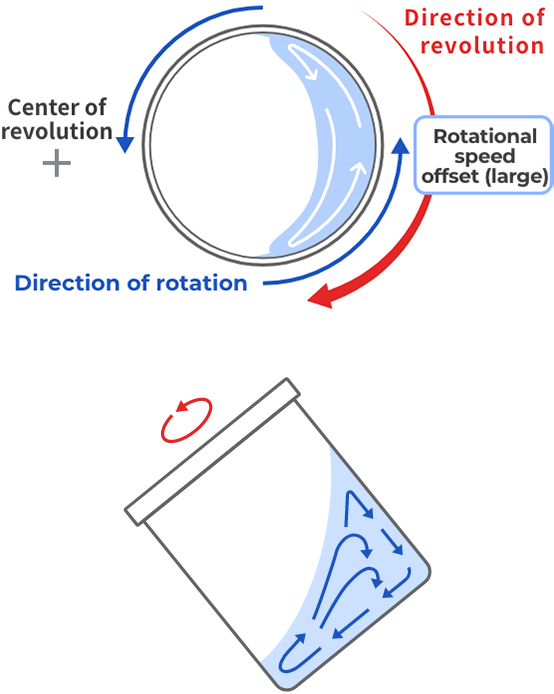

By rotating while revolving …

Shearing forces are generated between materials and cup sidewalls

MixingDefoaming

Generation of up-and-down convection flows

MixingDefoaming

Mixing / defoaming while preventing separation

MixingDefoaming

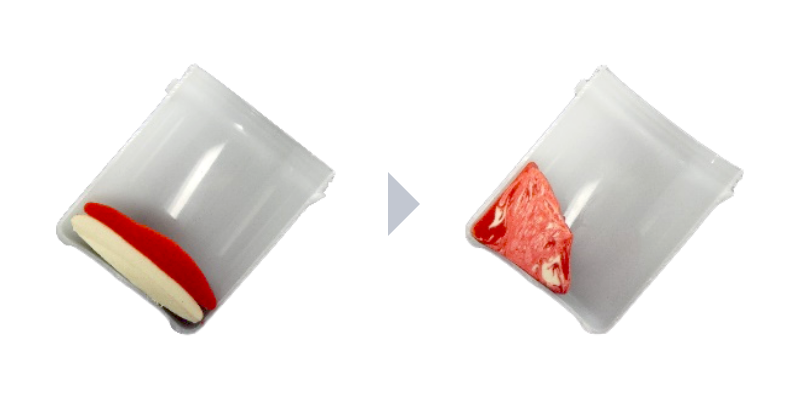

Bubble breaking effect by thin-film formation of materials

Defoaming

-

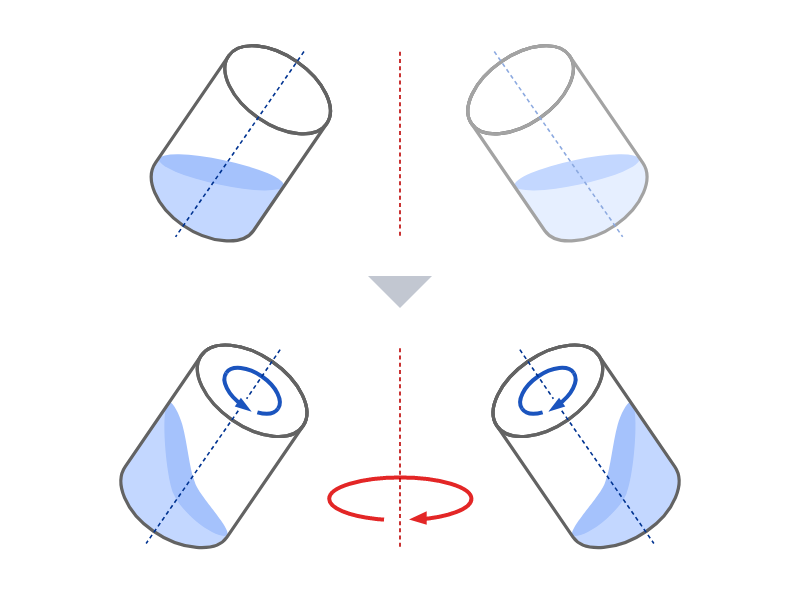

The containers revolve

Action of rotation

Centrifugal forces are given to materials

Effect of isolating air bubbles

-

Rotation starts simultaneously.

Action of rotation

Generation of vortex flows

-

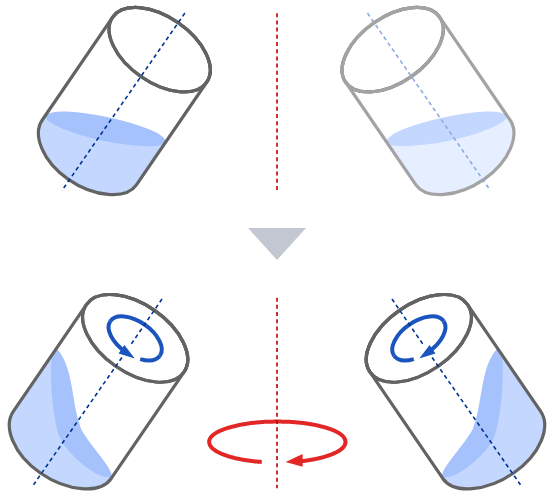

Vortex and up-and-down flows are generated and mixing proceeds.

Up-and-down convection flows of materials by cup inclination

Flowing in vortex form by torsional moment as up-and-down convection flows are generated by performing revolution and rotation simultaneously

-

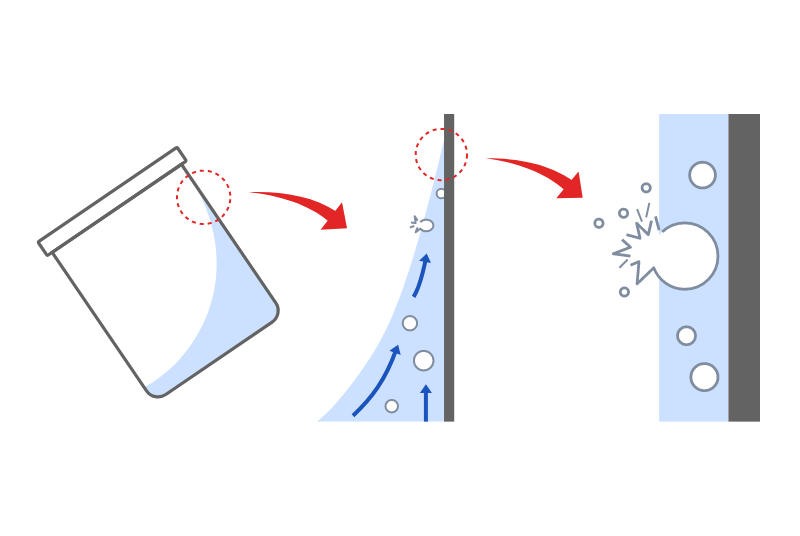

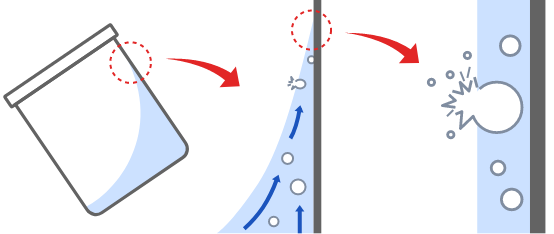

Defoaming is performed as bubbles are separated and broken

State of bubble breaking by thin-film formation of materials

As the materials flow, air bubbles also flow, but since strong centrifugal forces are exerted on materials, large air bubbles in the materials are broken near the center of the surface, and smaller air bubbles are broken as they are drawn out to form a thin film on cup sidewalls.

Kakuhunter Application and Introduction

Introduction Examples

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)