Kakuhunter SK-10000TV

· 7000 ml x 2 cups specifications

(max. weight 10kg x 2 cups)

· Easy operation with a liquid crystal

touch panel

· Compatible with SUS containers

· Optional handling assist

Throughput

10kg x 2 cups

Function

-

- Individual Revolution and Rotation Speed Control System

-

- Step Operation

-

- Vacuum Reduced Pressure Function

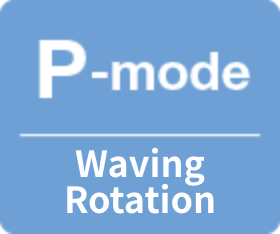

Mode

-

- Rotation speed creates up and down like wave, which enhances mixing force.

· Want to mix and defoam large-capacity

materials.

· Want to mix and defoam high-viscosity

materials and materials that are different

in specific gravities.

· Want to vacuum-defoam fine bubbles.

[Feature 1] Capacity / Throughput

· 7000ml container x 2 cups model!

· Can process up to 20kg (including the weight of 2 containers in total)

[Feature 2] SK-10000TV’s Unique Function

<Advantages of Cup Vacuum>

· It is now possible to set reduced pressure conditions twice as efficiently as before.

· Unnecessary pressure reduction is eliminated, reducing the load on the vacuum pump.

[Feature 3] Function Unique to “Kakuhunter”

(Unique Technology) Individual Speed Control System

With general models, the speed of revolution can only be input, and the speed of rotation is automatically set.

Therefore, requests cannot be met such as “to increase the speed of rotation a little more” and “to slightly reduce the speed of rotation since bubbles are formed.”

Our unique technology “individual speed control system,” which can combine 9 steps of revolution x 10 steps of rotation for 90 patterns, enables speed selections that are suitable for each material, resolving issues such as “mixing fails,” “lumps formed,” and “bubbles remain.”

Realizes a powerful ratio of revolution to rotation as revolution : rotation = 1:1

Powerful mixing can be performed since the speed of rotation can be set at up to 1:1 with respect to the speed of revolution.

Operable with zero rotation (revolution alone)

By setting the rotation to zero (revolution alone), the machine can be used in a wide range of applications, such as separating materials intentionally.

[Feature 4] Efficiency / Safety

Smoother Setting / Removal of Containers!

It is hard work to place heavy containers filled with materials on the cup trays and remove them from the cup trays.

Also, it is troublesome to make a half turn of the cup tray rotor by hand.

So,

(1) the “rotor stopping position setting function” that stops the rotor at a position that makes it easy to remove containers; and

(2) the “rotor 180-degree turning function” that moves the container on the opposite side to a position for easy removal

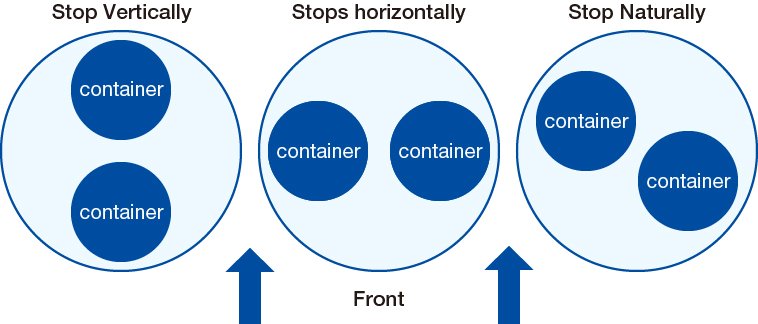

(1) What is the “rotor stopping position setting function?” The cup tray rotor stopping position at the end of running can be selected from the following 3:

(Schematic view from the top of the machine)

(2) What is the “cup tray rotor 180-degree turning function?” Pressing the button makes a half turn of the rotor (180-degree turn).

Since the other cup tray moves to the same position as the previously stopped cup tray, smooth setting / removal of containers can be expected.

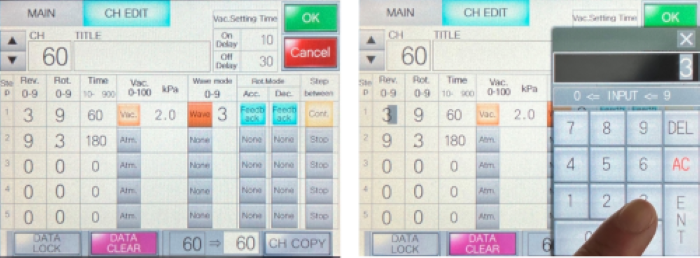

[Features 5] Adoption of a Liquid Crystal Touch Panel

With the Adoption of a Touch Panel!

· Just touch the place you want to enter.

· Numerical values of speeds, operating time, etc., can be entered directly from the pop-up numeric keypad.

There is no need for cursor movements with keys.

Initial screen Enter by using the numeric keypad

Operating Data is Displayed Graphically and Numerically

· Speeds of revolution and rotation, vacuum pressure, and other data can be displayed in graph or log form.

(*) The data download function is customizable.

Graph display Log data display

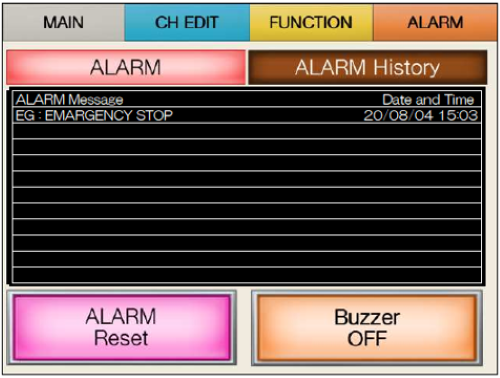

Error Information

· When an error occurs, the alarm and error information are displayed on the screen, allowing for a smooth response.

[Feature 6] Customization and Modifications

· Modifications according to your equipment standards

We respond to modifications flexibly according to your equipment standards, such as installation of a signal tower or revolving light, exhaust duct installation, and air purge mechanism.

If you have any requests, please feel free to consult us.

· Operating data log download function

Use the data for your quality control and process control.

■仕様

| Cup size |

7000ml commercially available containers or standard SUS containers [customizable] |

|

| Max throughput | 10kg (container included) x 2 cups [customizable] |

|

| Other containers | A variety of containers and syringes can be used by use of an adapter | |

| Speed of revolution | 100~400rpm Settable at 9 steps |

|

| Speed of rotation | with respect to 0 ~ 1.0 x revolution Settable at 10 steps |

|

| Setup time | Maximum 25 minutes (5 step total) | |

| Step mode | 5 steps Continuous operation can be performed with 5 different types of operation patterns (condition settings) |

|

| Conditions setting memory |

User-settable channels |

90 CH |

|

Fixed data channels |

10 CH | |

| Power supply voltage | Three-phase 200-240V 50/60Hz |

|

| Power consumption | Max 18kW | |

| External dimensions | W1900×D1300×H980(mm) (excluding external vacuum pump) |

|

| Weight of the main unit | Approx. 1530 kg (excluding external vacuum pump) | |

* It differs machine throughput depending on materials characteristic.

* Revolving speed may change depending on materials characteristic.

* Detailed specification may change without prior notice.

Brochure DownloadFree

Includes product specifications and useful information that help you select a product.

The brochure may also be used with the Ringi system, etc.

Download a brochure from here (free)

* You will be redirected to a page on another domain managed by us.

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

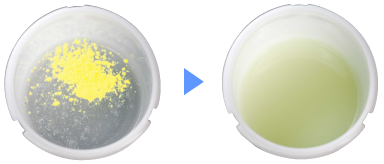

Dispersing

Example material: Fluorescent powder + Resin

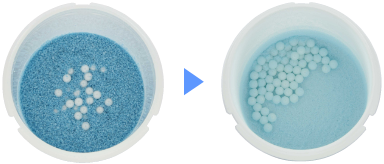

Crushing

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

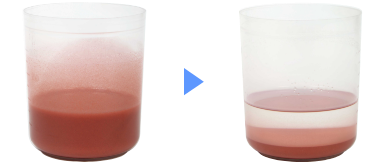

Separating

Example material: Adhesive + Colored stone

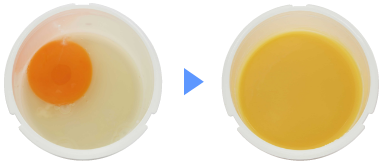

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)