Kakuhunter SK-300TVS-A

· Model with a high functional vacuum reduced

pressure feature.

· By the individual revolution and rotation

speed control system and shifted cup tray

mechanism, the mixing ability is improved and

effective defoaming is realized.

Throughput

300ml (300g) x 2 cups

Function

-

- Individual Revolution and Rotation Speed Control System

-

- Step Operation

-

- Vacuum Reduced Pressure Function

-

- Shifted Cup Tray

· Want to mix and defoam small amounts of

materials for research and development.

· Want to mix and defoam high-viscosity

materials and materials that are different in

specific gravities.

· Want to vacuum-defoam fine bubbles.

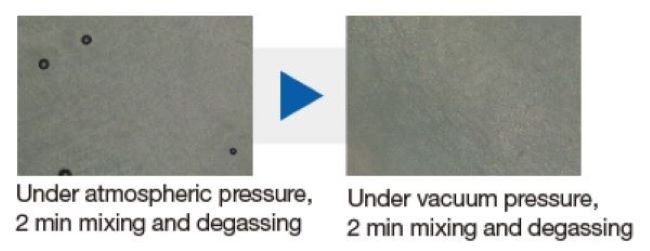

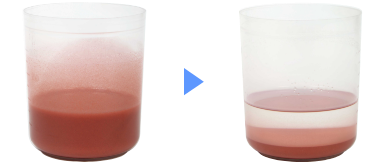

Defoaming Ability Enhanced with a Vacuum Unit!

Finer bubbles can be removed, improving conductivity and insulation properties required for electronic materials, reducing the rate of defectives in products resulting from bubbles in optical materials, and preventing air shots from syringes due to air bubbles.

Mixing Ability Enhanced With the Adoption of Shifted Cup Trays on the Rotation Axis!

Since cup trays on the rotation axis are shifted to increase the contact surfaces between containers and materials, compared with the conventional machines (vertical cup trays), the mixing ability is enhanced and materials hardly form lumps. Furthermore, uniform mixing can be performed since long containers, such as barrels and syringes, can also be set, maintaining a distance from the revolution axis.

■ Specifications

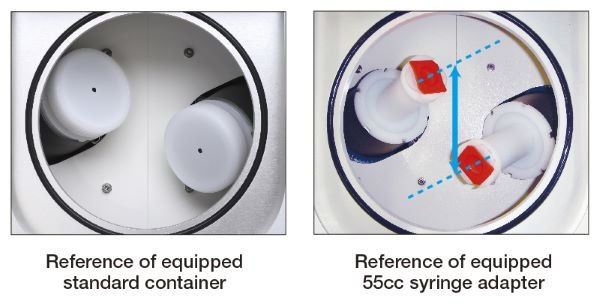

| Cup size | 300ml x 2cups Various syringes of 55cc or less |

|

| Max throughput | 310g x 2cups | |

| Other containers | A variety of containers and syringes can be used by use of an adapter | |

| Speed of revolution | Settable at 9 steps | |

| Speed of rotation | Settable at 10 steps (However, there are some restrictions depending on the speed of revolution.) |

|

| Setup time | Maximum 25 minutes (5 step total) | |

| Step mode | 5 steps Continuous operation can be performed with 5 different types of operation patterns (condition settings) |

|

| Conditions setting memory | User-settable channels | 90 CH |

| Fixed data channels | 10 CH | |

| Power supply voltage | Single-phase 100-115V Single-phase 200-230V 50/60Hz |

|

| Power consumption | 1.5kW | |

| External dimensions | W445 x D555 x H495 (mm) (excluding external vacuum pump) | |

| Weight of the main unit | Approx. 80 kg (excluding external vacuum pump) | |

*Vacuum Pump Box is not included as an optional equipment.

* It differs machine throughput depending on materials characteristic.

* Revolving speed may change depending on materials characteristic.

* Detailed specification may change without prior notice.

Brochure DownloadFree

Includes product specifications and useful information that help you select a product.

The brochure may also be used with the Ringi system, etc.

Download a brochure from here (free)

* You will be redirected to a page on another domain managed by us.

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Atmospheric Pressure Models

Optimum settings for materials by easy operation

Vacuum Equipped Models

In further pursuit of defoaming

High-spec Models

Realization of high performance with a simple mechanism

Exclusive Models

Diverse types of mixing

with one unit -

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

Dispersing

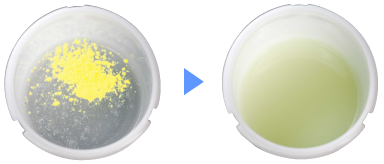

Example material: Fluorescent powder + Resin

Crushing

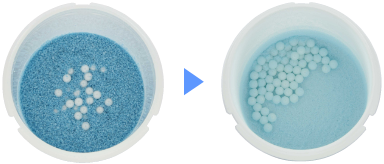

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

Separating

Example material: Adhesive + Colored stone

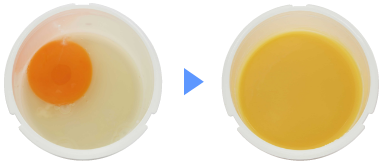

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)