Non-contact Temperature Sensor

Optional product for Kakuhunter that can measure and monitor the temperatures of materials being mixed

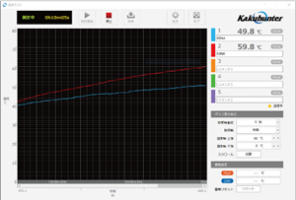

- Displays temperature information received by the temperature sensor in real time.

- Displays an alarm when the measured temperature exceeds the set upper limit or lower limit.

- Measured temperature information can be output in a CSV format file.

- Compatible with three types of containers: 300ml / 400ml / 1100ml

Optional product for Kakuhunter with a set of 3 tools

-

Our standard container *1 coming with

[Temperature sensor + Transmitter] -

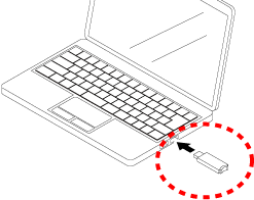

[Receiver]

inserted

into a USB port of a personal computer*2 -

[Application]

Graph drawing software for personal computer

- Three types of containers with a temperature sensor are available in 300ml / 400ml / 1100ml. For attachment to other containers, please feel free to consult us.

- Personal computer is not included in this set.

Recommended for These Cases Where:

· Materials are damaged by temperature rises.

· Materials harden with temperature rises.

· The composition of materials changes or their components volatilize, etc.

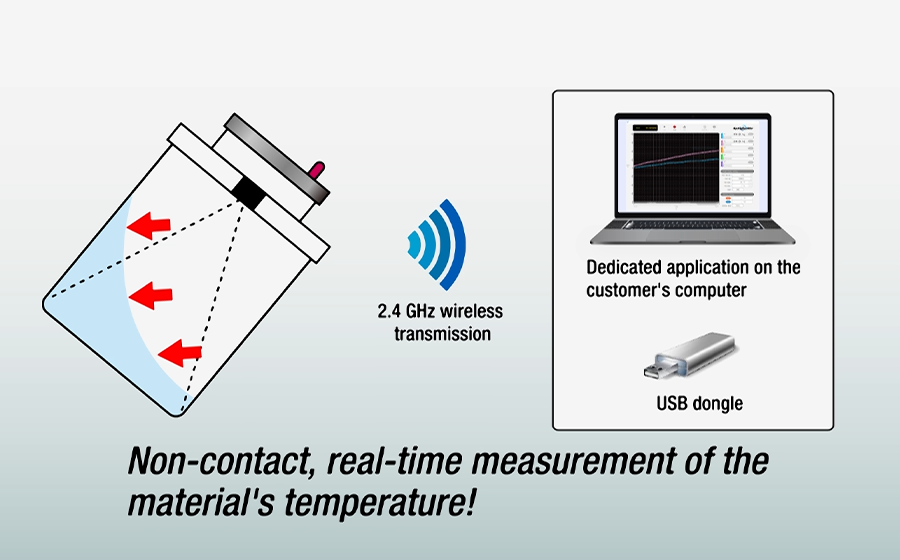

Temperatures of materials are measured in a non-contact manner in real time by using an infrared temperature sensor

By using this product, the temperatures of materials being mixed by the planetary centrifugal mixer “Kakuhunter” can be easily measured in a non-contact manner, and temperature data is sent to your personal computer in real time. By installing the included software onto your personal computer, you can wirelessly obtain temperature data and graph it.

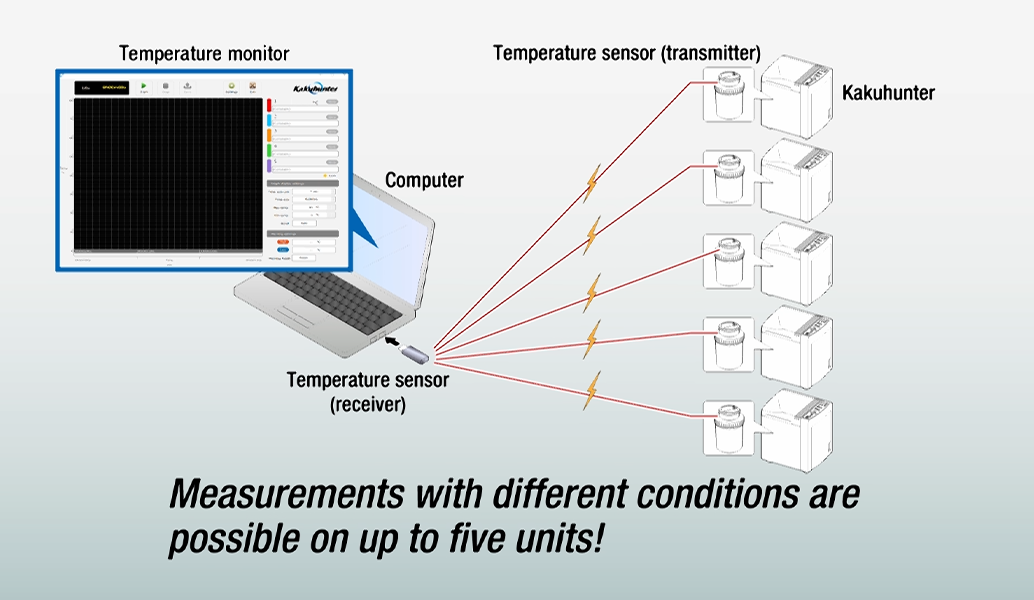

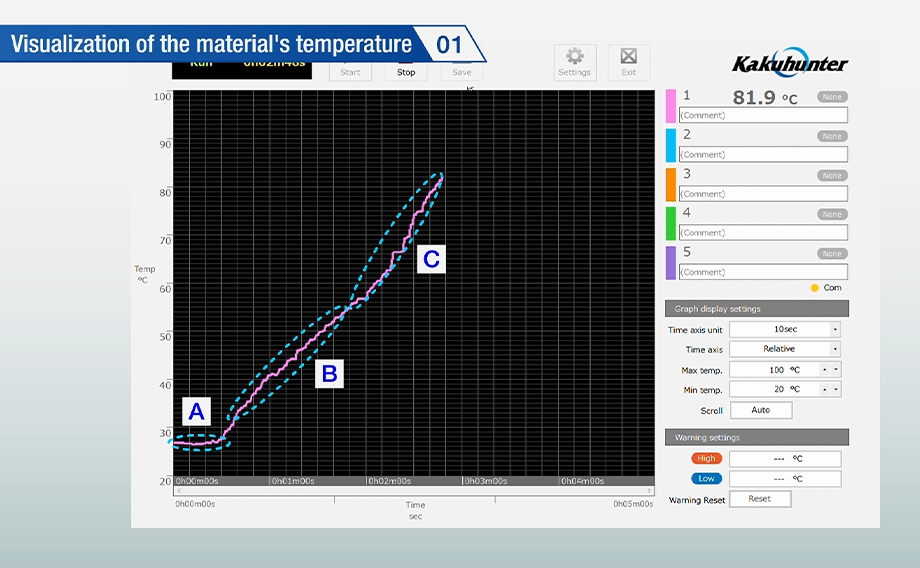

Up to 5 Temperature Changes of Materials are Monitored.

Up to 5 temperatures of materials being mixed in containers can be displayed on a graph!

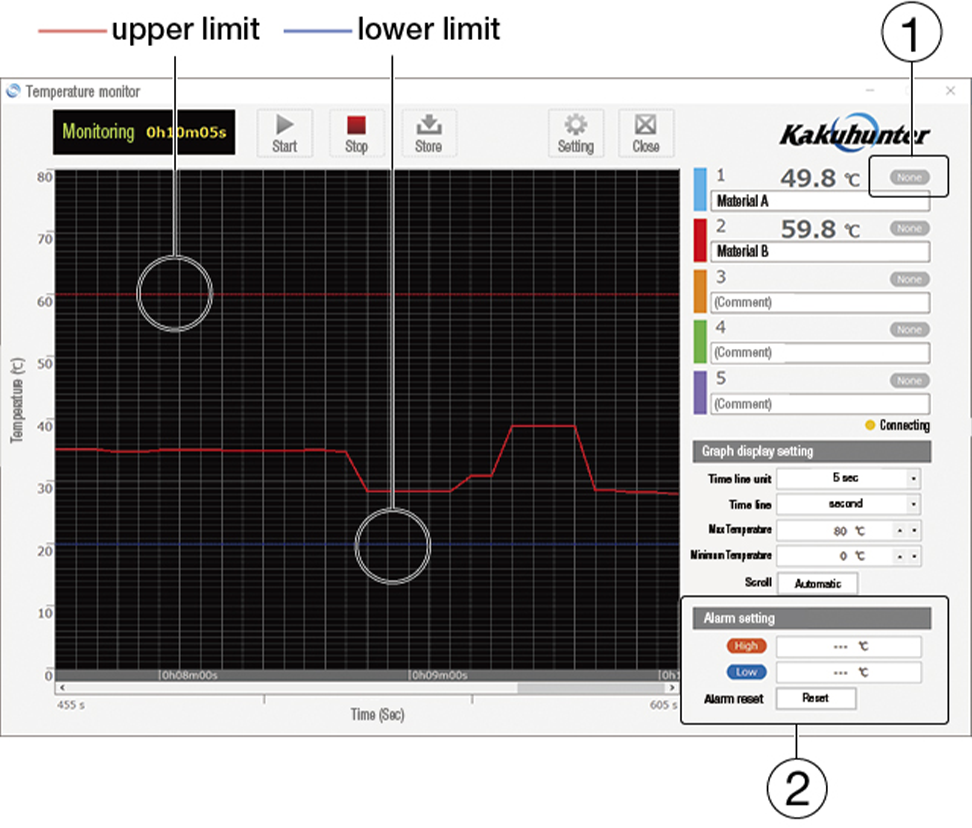

Set colors are displayed in (1) on the main screen, and each graph (2) is also displayed in the set colors with the start of measurement.

* Colors can also be set by clicking the color chips in (1).

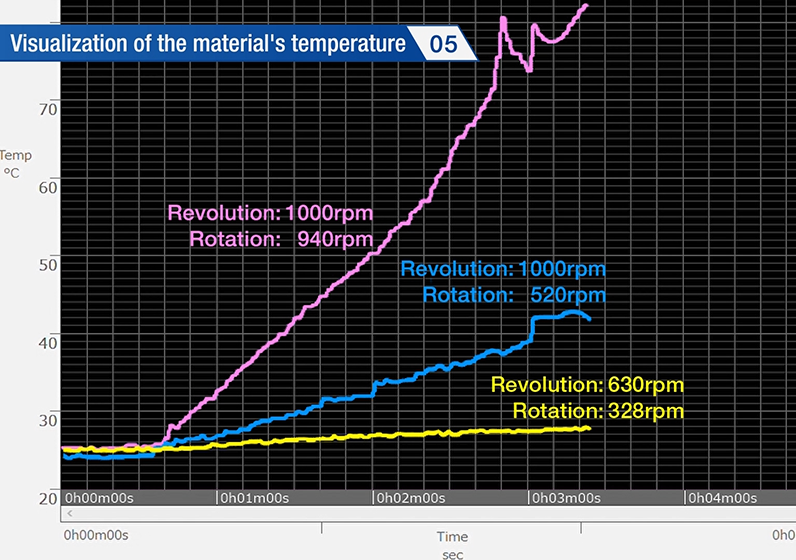

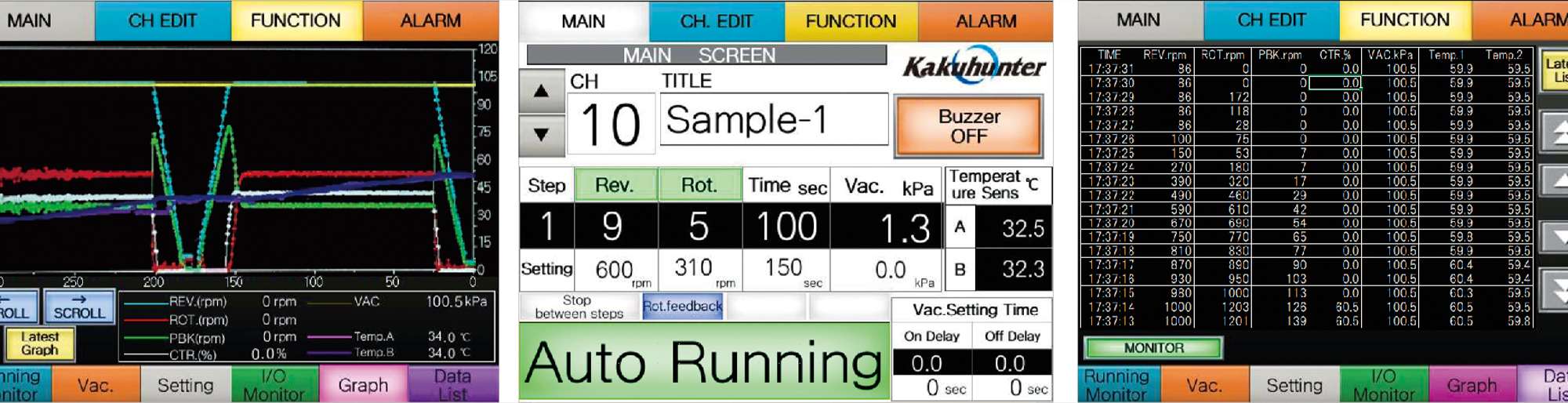

The speeds of revolution and rotation, temperature rises, etc., can be monitored simultaneously!

During operation, the speeds of revolution / rotation and the temperature transitions of materials can be monitored simultaneously.

This facilitates the setting of optimum operating conditions according to material characteristics.

An alarm is displayed by setting the upper limit and lower limit temperatures.

The alarm can be set by the upper limit x lower limit temperatures!

When the alarm is set, the upper limit is indicated by red dashed lines, and the lower limit by blue dashed lines on the graph display.

If the set temperature is exceeded, it is notified on the monitor! Extremely useful in preventing excessive temperature rises!

After the start of measurement, if the temperature exceeds the set upper limit (or becomes equal to the upper limit), [None] on the display (1) changes to [High], and if the temperature exceeds the lower limit (or becomes equal to the lower limit), it changes to [Low], indicating that the alarm set value has been exceeded.

The alarm values (upper limit / lower limit) set at the beginning are displayed on the settings display (2).

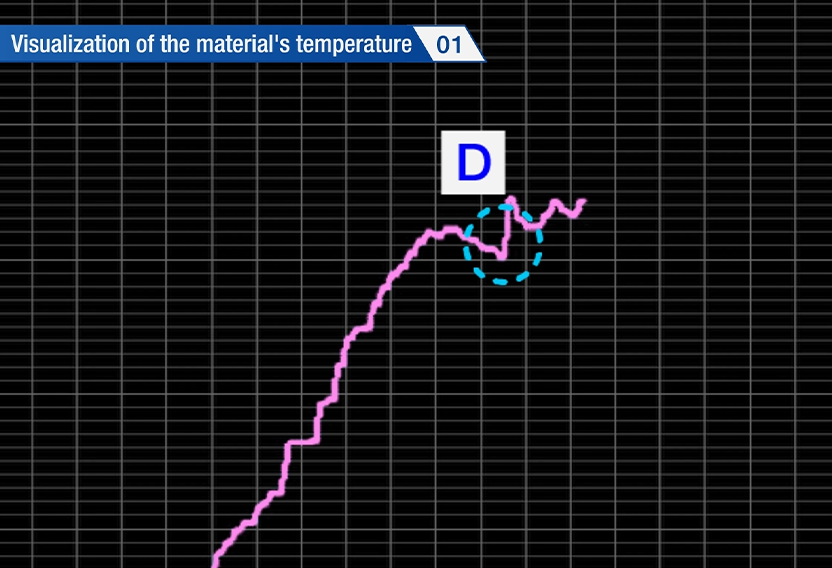

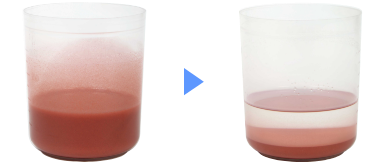

Changes of materials being mixed and guidelines for taking measures

The progress of mixing can be estimated from temperature transition

During mixing, there is little temperature rise at the initial point (A), and as time pass, the temperature rises to (B) to (C). Eventually, the flowability of materials increases, and there is a moment when the stagnant materials move significantly inside the containers, and the moment is judged as point (D) where the mixing is assumed to have advanced. After that, the point where the temperature transition has stabilized is the timing to check the state of mixing.

Points in Managing Material Temperatures

The mixing and defoaming quality of materials is extremely important for manufacturing.

However, there are various issues with temperature rises as follows:

- Materials are damaged by temperature rises.

- Materials harden with temperature rises.

- The composition of materials changes or their components volatilize, etc.

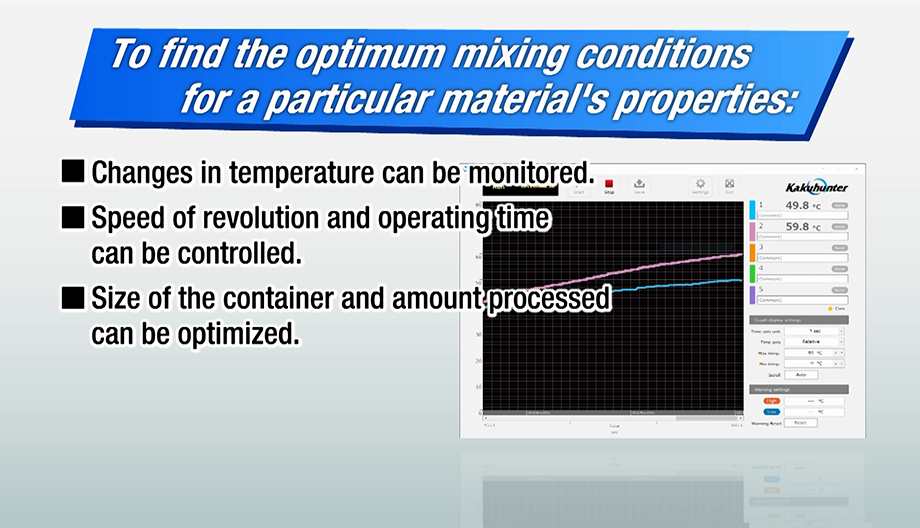

Suggestion of Optimum Mixing Conditions According to Material Characteristics

- Monitoring of Temperature Transition

- Control of rotational Speed and Operating Time

- Optimization of Container Size and Content Quantity

- Use of an Adapter for Cooling and Other Measures to Exhaust Heat from within the Machine, etc.

In addition to the control of rotational speed and operating time, optimization of container size and content, cooling, and other measure to exhaust heat, “visualization of temperature transition” is an important point.

Good control of temperature transition during mixing will lead to stable and improved quality.

Suggestion of Measures to Suppress Temperature Rises of Materials

From measurements with the “non-contact temperature sensor,” Kakuhunter’s “medium mode,” “Individual Speed Control system,” “step mode,” and other extensive functions are effective as measures to suppress temperature rises of materials.

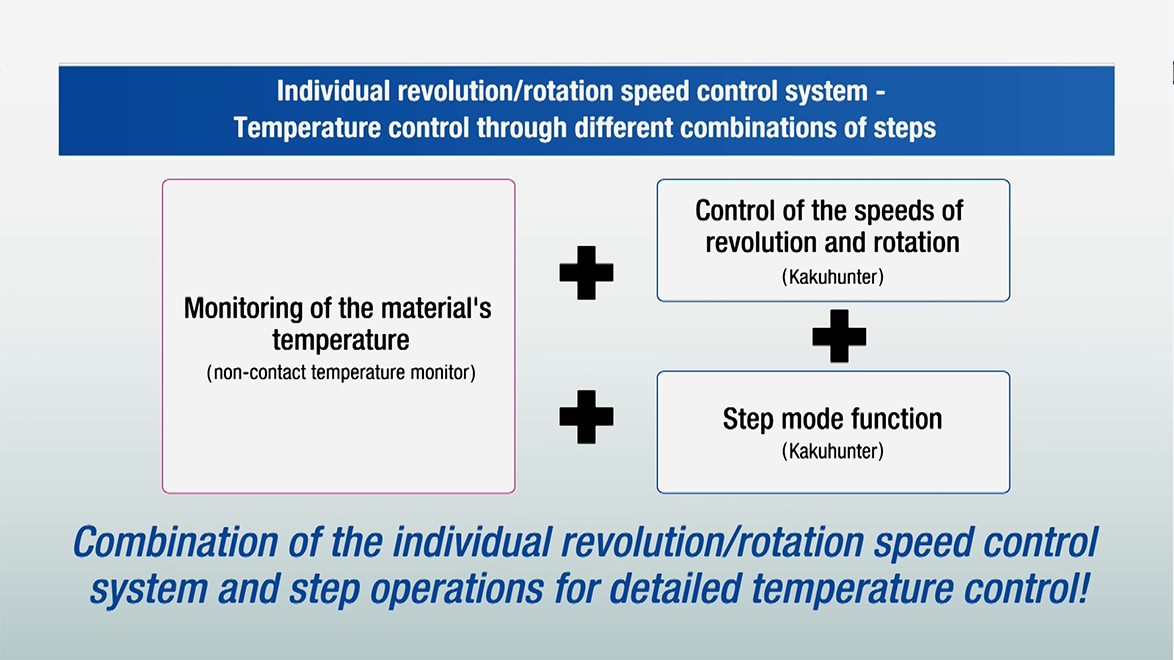

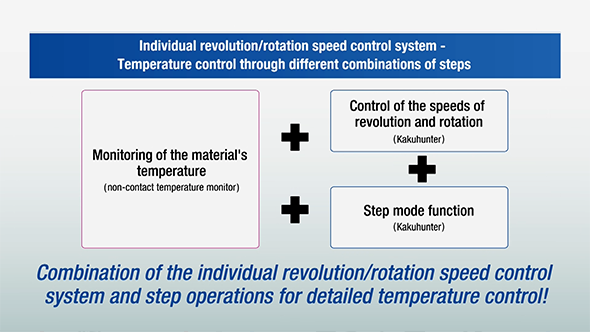

Individual Revolution and Rotation Speed Control System and Step Mode

By combining the “Individual Speed Control system” in which the ratio of revolution to rotation can be changed, and the “step mode” in which continuous running of multiple different operation patterns can be performed, temperature control of materials with various characteristics can be handled across a wide range.

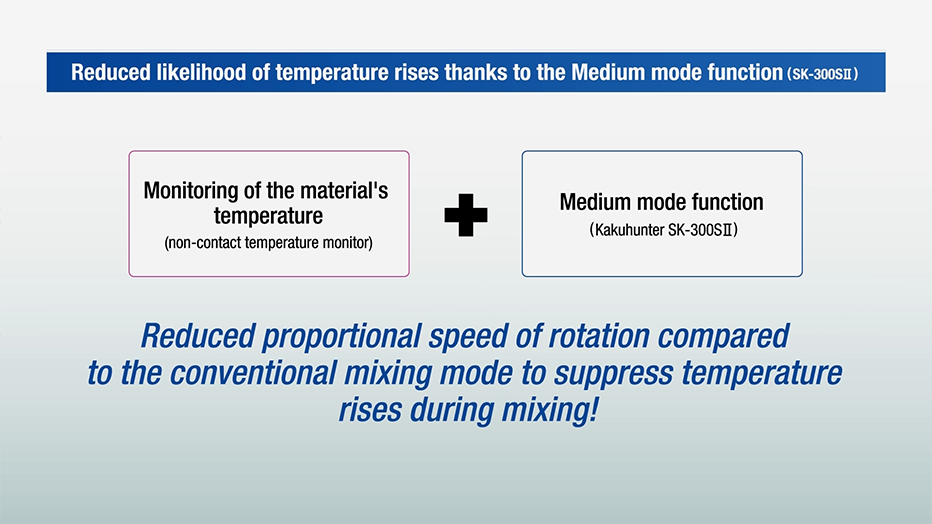

Medium Mode Function (SK-300SII only)

The medium mode function of the Kakuhunter “SK-300SII” can decrease the ratio of rotation from the mixing mode. This suppresses the generation of heat of mixing, and also corresponds to mixing and defoaming of materials that are delicate in temperature rises.

Strong support for “setting of mixing conditions” for materials that are delicate in temperature changes through the “visualization” of material temperatures

As main applications, support is provided for not only guidelines for control of material temperatures and management of the mixing process, but also detection of errors in the amounts of materials and their formulation, confirmation and verification of heat of mixing, etc.

Main Applications

- Guidelines for control of material temperatures

- Management of the mixing process

- Detection of errors in the amounts of materials and their formulation, etc.

- Confirmation and verification of heat of mixing by viscosity difference between materials

“Non-contact Temperature Sensor” Q&A

- Can a temperature sensor be used alone?

- Our sensor is designed to be attached to the lid of a resin container used in Kakuhunter, and it cannot be used alone.

- Can measured temperature data be output?

- It can be downloaded in a CSV format file.

- Can a non-contact temperature sensor be tested with an actual machine?

- Yes. But please contact us first.

Specifications

| Item | Description |

|---|---|

| Sensor type | Infrared temperature sensor |

| Measurement range | 0 ~ 80°C*1 |

| Resolution (minimum reading) | 0.1°C |

| Power supply | Coin cell lithium battery |

| Battery life (transmitter) | Continuous running approx. 200 hours |

| Dimensions | Transmitter: Overall height approx. 118mm (including a standard container) *2 Receiver: USB dongle |

| Mass | Transmitter: Approx. 61g (including a top lid unit and battery) *2 |

Measurement values may fluctuate depending on the materials to be measured and usage environment, etc.

Specifications are subject to change without notice.

- The performance of the temperature sensor is between -40°C ~ +125°C.

- In the case of standard container No.002.

Brochure Download Free

Includes product specifications and useful information that helps you select a product.

Download a brochure from here(free)

※ 弊社が管理する別ドメインのページへ遷移します。

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

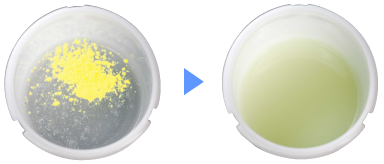

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

Dispersing

Example material: Fluorescent powder + Resin

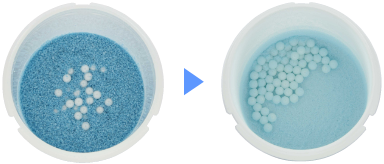

Crushing

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

Separating

Example material: Adhesive + Colored stone

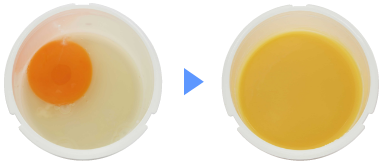

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)