Kakuhunter SK-300SⅡ

SK-300SII’s Unique Mechanism

■ Medium Mode

Generation of heat from mixing is suppressed

by lowering the ratio of rotation from the

conventional mixing mode, and materials that

are sensitive to temperature rises can also be

processed.

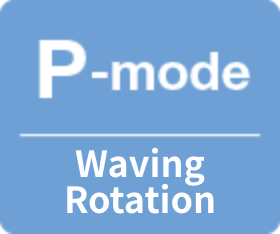

■ Wave Mode

Mixing / dispersing can be performed more

smoothly and effectively by accelerating and

decelerating the speeds of revolution and

rotation.

Throughput

300ml (310g) x 1 cup

Function

-

- Fixed ratio for revolution-rotation

-

- Step Operation

Mode

-

- Rotation speed creates up and down like wave, which enhances mixing force.

· Want to mix and defoam high-viscosity

materials and materials that are different in

specific gravities.

· Want to mix and defoam a wide variety of

materials with one unit.

Mode Setting According to Application

For the SK-300SII, the medium mode is newly added to the conventional “mixing mode / defoaming mode.”

While easy operation remains unchanged, it is now possible to select modes to suit a wider range of applications and materials.

Equipped with a Balance Navigation Function

The balance can be adjusted easily by unbalance detection and the balance navigation function.

Compatible with 300ml Containers / Max. 310g

While the machine is compact, processing of 300ml containers weighing a maximum of 310g (gross weight) can be processed!!

Fully Safe Design

The safety-conscious design includes mechanisms to lock the top lid during operation, to prevent operation when the top lid is open, and to prevent malfunctions.

In addition, you can use the machine with peace of mind thanks to the comprehensive alarm/notification functions, including unbalance detection, motor abnormality, and maintenance.

■ Specifications

| Cup size | 300ml x 1 cup Various syringes of 30cc or less |

|

| Max throughput | 310g x 1 cup | |

| Other containers | A variety of containers and syringes can be used by use of an adapter | |

| Speed of revolution | Mixing mode | 200~2000rpm |

| * Medium mode | 200~2000rpm | |

| Defoaming mode | 400~2200rpm | |

| Speed of rotation | Mixing mode | Follow-up at 40% with respect to the revolution |

| * Medium mode | Follow-up at 20% with respect to the revolution | |

| Defoaming mode | Follow-up at 3% with respect to the revolution | |

| Settable time | Max 30 min. (total of 9 steps) | |

| Step mode | 9 steps Continuous operation can be performed with 9 different types of operation patterns (condition settings). |

|

| Conditions setting memory | User-settable channels | 7 CH |

| Fixed data channels | 3 CH | |

| Power supply voltage | Single-phase 100-120V Single-phase 200-240V 50/60Hz |

|

| Power consumption | 0.4 kW/1.38kW | |

| External dimensions | W340×D315×H370(mm) | |

| Weight of the main unit | Approx. 24kg | |

: Above descriptions may change without notice.

*・Medium mode/Wave mode are exclusively for SK-300SII.

・Wave mode has revolving speed limitation ( Revolution: 1,000-1,790 rpm/ Rotation: about 400-716rpm)

Brochure DownloadFree

Includes product specifications and useful information that help you select a product.

The brochure may also be used with the Ringi system, etc.

Download a brochure from here (free)

* You will be redirected to a page on another domain managed by us.

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Atmospheric Pressure Models

Optimum settings for materials by easy operation

Vacuum Equipped Models

In further pursuit of defoaming

High-spec Models

Realization of high performance with a simple mechanism

Exclusive Models

Diverse types of mixing

with one unit -

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

Dispersing

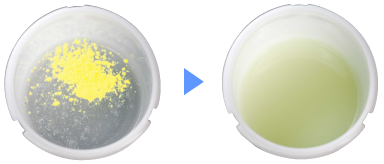

Example material: Fluorescent powder + Resin

Crushing

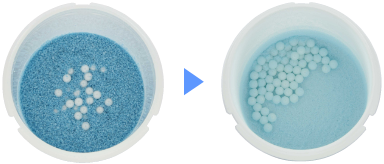

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

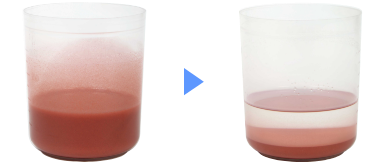

Separating

Example material: Adhesive + Colored stone

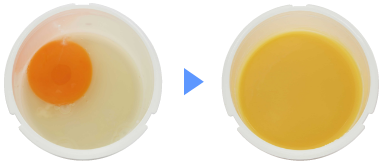

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)