Kakuhunter SK-BS12T

Barrel / syringe-specific planetary centrifugal mixer that enables setting 12 oz barrels (360ml) and 6 oz (180ml) barrels.

· By the individual revolution and rotation

speed control system, uniform mixing of

materials and removal of fine air bubbles are

realized in a short time.

· By using barrels (12 oz, 6 oz) properly

according to production volume, productivity

and workability can be improved.

* For use of 6 oz barrels, dedicated adapters

(spacers) are required.

Throughput

2kg x 2cups

Function

-

- Individual Revolution and Rotation Speed Control System

-

- Step Operation

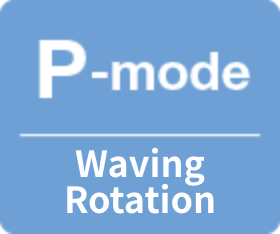

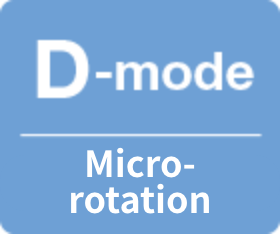

Mode

-

- Rotation speed creates up and down like wave, which enhances mixing force.

-

- Due to slight move of revolution, which enables to eliminate micro fine bubbles.

-

- Mixing power and liquid, then avoid to occur lump condition.

· Have trouble in mixing materials that are

different in specific gravities.

· Want to defoam air bubbles that occur during

transfer from other containers.

· Fail in quantitative discharge due to air

bubbles remaining in syringes.

· Do not want to break the composition of

materials with a mixing rod or propeller.

· In addition, want to eliminate the loss of

materials.

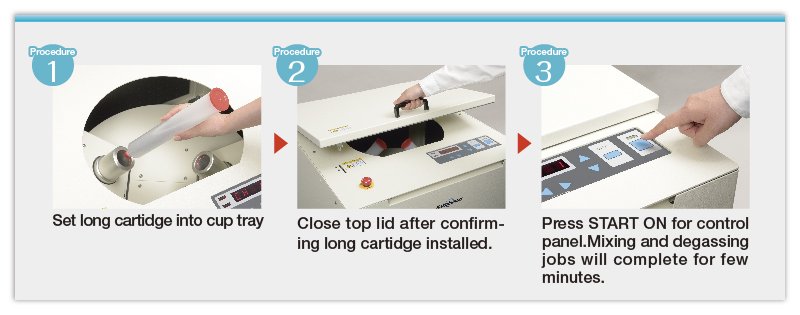

■ Operating Method

Issues arising in quantitative discharge with a dispenser are resolved all at once!

▶ Air bubbles in syringes can be efficiently defoamed to improve the filling accuracy.

■ Specifications

| Cup size | 12oz, 6oz Long cartridge x 2pcs |

|

| Max throughput | 2kg x 2 cups | |

| Speed of revolution | Settable at 9 steps | |

| Speed of rotation | Settable at 10 steps | |

| Settable time |

Maximum 25 minutes (5 step total) |

|

| Step mode |

5 steps Continuous operation can be performed with 5 different types of operation patterns (condition settings) |

|

| Conditions setting memory | User-settable channels | 90 CH |

| Fixed data channels | 10 CH | |

| Power supply voltage |

Three-phase 200-240V Three-phase 380-415V 50/60Hz |

|

| Power consumption | 2.5kW | |

| External dimensions | W646×D663×H851 (mm) | |

| Weight of the main unit | Approx. 225kg | |

* It differs machine throughput depending on materials characteristic.

* Revolving speed may change depending on materials characteristic.

* Detailed specification may change without prior notice.

Brochure DownloadFree

Includes product specifications and useful information that help you select a product.

The brochure may also be used with the Ringi system, etc.

Download a brochure from here (free)

* You will be redirected to a page on another domain managed by us.

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

Mixing

Example material: Printing ink

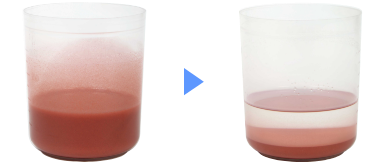

Defoaming

Example material: High-viscosity adhesive

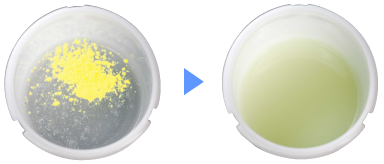

Dispersing

Example material: Fluorescent powder + Resin

Crushing

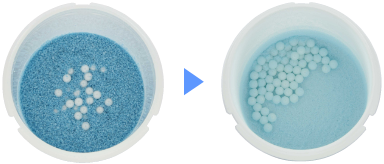

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

Separating

Example material: Adhesive + Colored stone

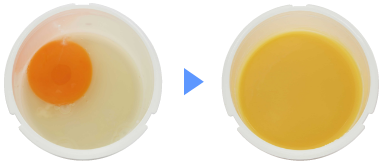

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)