Syringe Filling Machines [SJ series]

Bubbleless & High-precision Filling

Reliable quality achieved through automation

High-precision, high-efficiency filling of mixed materials into syringes

The container for Kakuhunter can be set directly into the filling machine.Prevents air bubbles from getting mixed in and discharge failure when handling high-viscosity materials

-

Handling large-capacity barrels

modelSJ-1200

[Automatic model]

-

For small-capacity syringes

modelSJ-800

[Tabletop model]

-

SJ-1200[Automatic model]

Automatic syringe filling machine that can handle even large-capacity barrels and achieves high-precision filling

- Prevents air bubbles from getting mixed while filling materials.

- A wide range of parameters according to material viscosity are available.

- For automatic filling, settings can be made for up to 99 channels.

(Various syringe samples have already been preset : for 10 channels) - As applicable syringes, products made by respective dispenser manufacturers can be used.

- The container for Kakuhunter can be set directly into the filling machine.

- Simple structure for easy cleaning.

- Equipped with an easy-to-operate touch panel.

SJ series are the solution.

Do you have any of these concerns?

- Concerned about quality variations and bubble contamination with manual filling.

- Want to prevent underfilling or overfilling.

- Transferring the defoamed material into another container is time-consuming.

- With a pressure tank system, high-viscosity materials can get stuck and won’t go in.

- With other methods, it’s difficult to finely adjust filling amounts.

- Consistent filling is difficult.

Our filling machines are the solution.

- Quality variation and air contamination can be reduced by a wide range of parameters, and materials can be finely adjusted.

- The table-lift system, which has a high filling load.

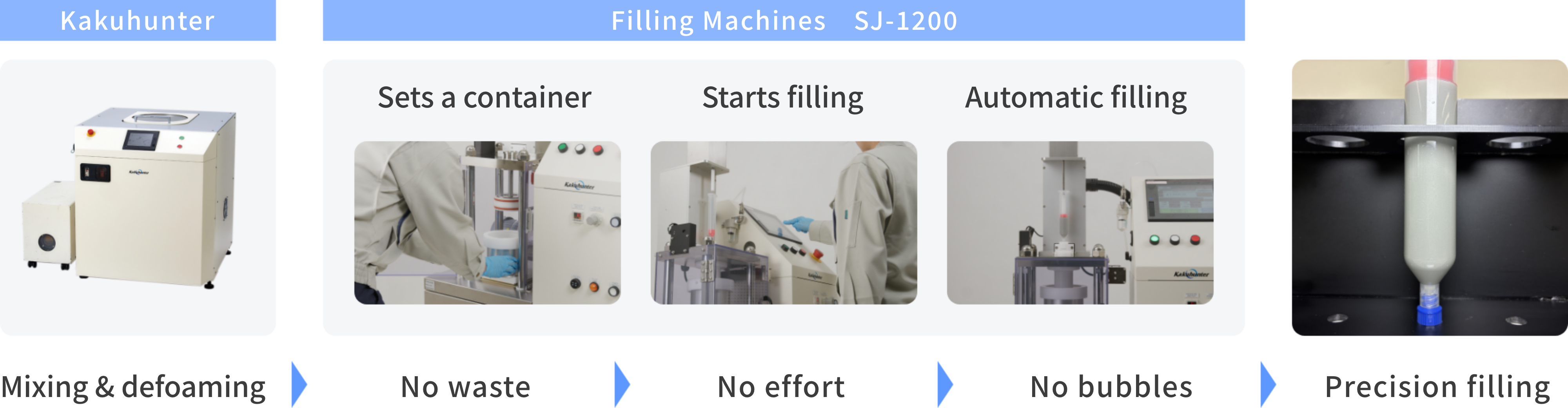

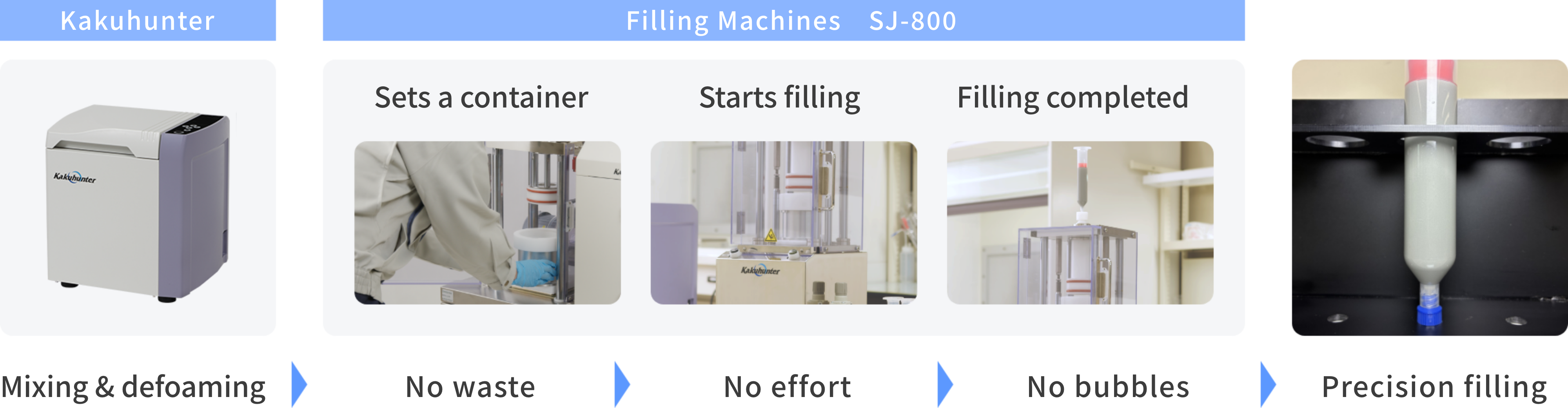

One-stop solution from mixing to filling

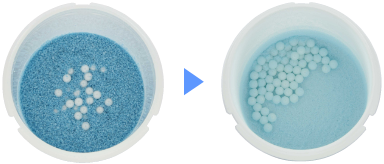

Reduction in “time loss” and “material waste”By using our filling machine in combination with our planetary centrifugal mixer “Kakuhunter,” the process of transferring into another container is eliminated and efficient and high-precision filling is achieved.

The time loss and material loss caused by manual operation or other filling methods are reduced, leading to improved production efficiency.

Filling mechanism and features

Table-lift system

As containers with mixed and defoamed materials are fixed on the table, syringes are directly filled by pistons.

Features

- The high filling load of the filling machine makes it suitable for filling highly viscous and thixotropic materials.

- As material containers are fixed on the precisely controlled table, syringes are directly filled through container adapters.

⇒They can be filled efficiently because the pathways of materials are straight and short. - Since no valve is used, the liquid contact parts are structured with extreme simplicity, and filling can be performed to the end of the amounts remaining in containers with little loss.

Parameter settings enable extremely small amount adjustments

A wide range of parameters according to material viscosity

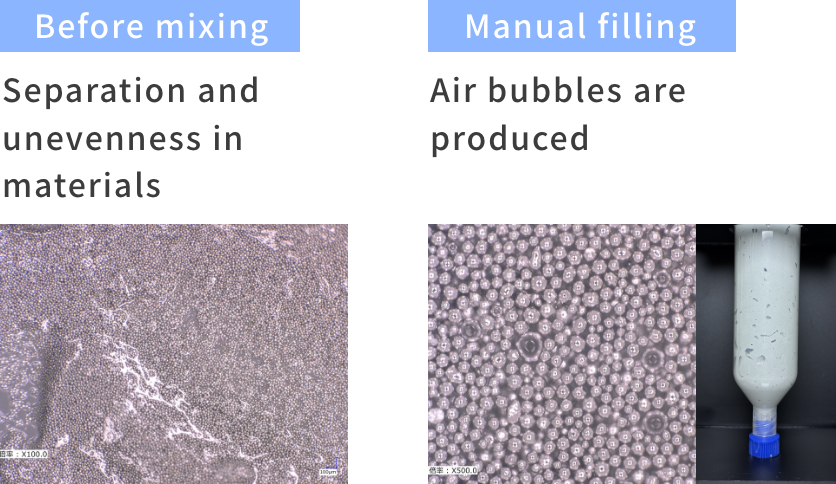

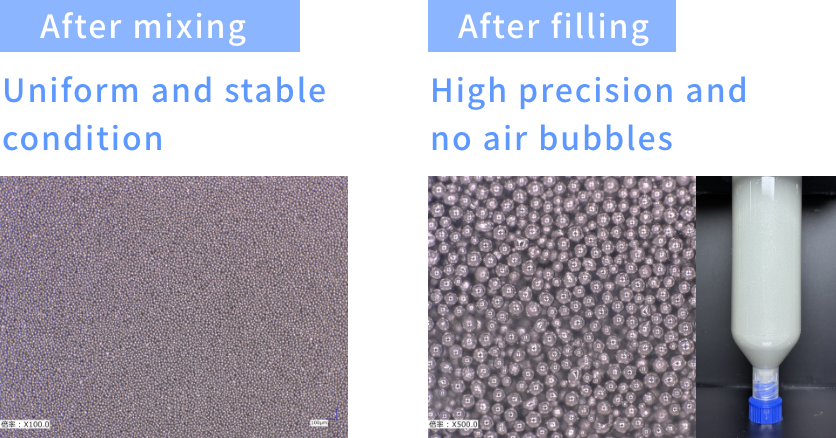

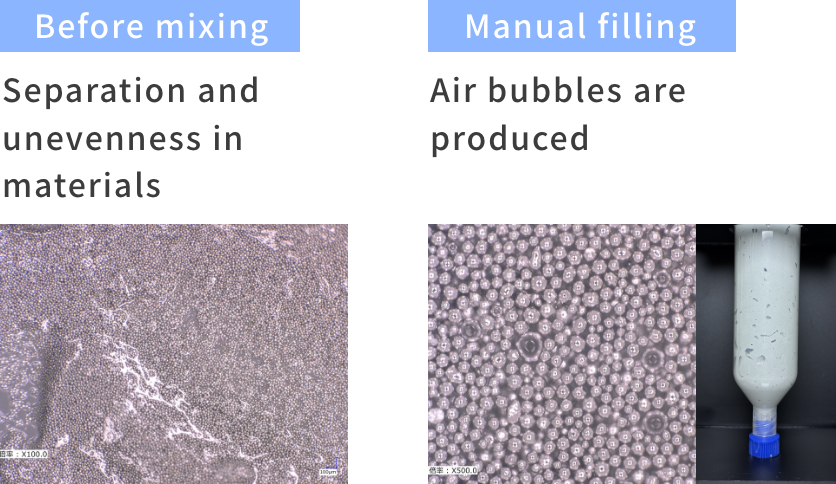

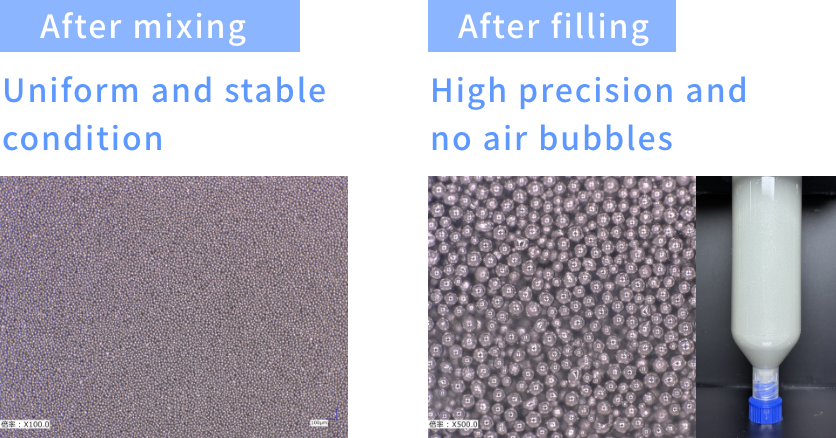

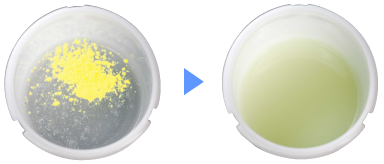

finely adjust material volume and keep consistent filling.Case ~High-precision mixing, defoaming, and filling~

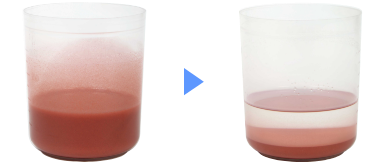

Material used: Solder paste, Viscosity: 220Pa·s

Before

The solder paste is highly viscous and easily separates, causing problems such as air bubbles and uneven filling in manual operation.

This can cause poor quality or material clogging.

After

By combining our planetary centrifugal mixer and filling machine, material uniformity and air bubble removal are achieved at the same time.

Precise control enables stable filling with high precision even when handling a small amount of materials.Industries and materials

- Electronic components industry(Thermal grease, silver paste, heat dissipation grease, etc.)

- In-vehicle/automotive industry(Ceramics, solder paste insulating materials, rubber-based adhesives, etc.)

- Dental industry(Composite resins, powder slurries, etc.)

Compatible with a wide range of syringes and barrels

The SJ series is compatible with special syringes, barrels and products from various manufacturers.

Please feel free to contact us.Compatible size SJ-1200 SJ-800 3ml 〇* 〇* 5ml 〇* 〇* 10ml 〇 〇 20ml 〇 〇 30ml 〇 〇 50ml 〇 〇 55ml 〇 〇 70ml 〇 - 2.5oz 〇 〇* 100ml 〇 - 6oz・170ml 〇 - - *Compatible by adding optional parts.

Specifications

Item Description method Automatic Filling method Table-lift system Material container Standard container available (approx. 1120ml container) Outer dimensions W810 x D472 x H1613 (mm)

(*Not including the handle and other projections)Weight Approx. 300kg Power supply voltage Single-phase 100-120V AC

Single-phase 200-240V AC 50/60HzRequired air pressure 0.4MPa or more - *Specifications are subject to change without notice.

-

SJ-800[Tabletop model]

Tabletop filling machine that can fill small-capacity syringes with high precision and efficiency

- Prevents air bubbles from getting mixed while filling materials.

- Compact size that can be installed anywhere.

- As applicable syringes, products made by respective dispenser manufacturers can be used.

- The container for Kakuhunter can be set directly into the filling machine.

- No need of a power supply.

- Easy filling with just a button operation.

- Simple structure for easy cleaning.

SJ series are the solution.

Do you have any of these concerns?

- Concerned about quality variations and bubble contamination with manual filling.

- Want to prevent underfilling or overfilling.

- Transferring the defoamed material into another container is time-consuming.

- With a pressure tank system, high-viscosity materials can get stuck and won’t go in.

- With other methods, it’s difficult to finely adjust filling amounts.

- Consistent filling is difficult.

Our filling machines are the solution.

- Quality variation and air contamination can be reduced by a wide range of parameters, and materials can be finely adjusted.

- The table-lift system, which has a high filling load.

One-stop solution from mixing to filling

Reduction in “time loss” and “material waste”By using our filling machine in combination with our planetary centrifugal mixer “Kakuhunter,” the process of transferring into another container is eliminated and efficient and high-precision filling is achieved.

The time loss and material loss caused by manual operation or other filling methods are reduced, leading to improved production efficiency.

Filling mechanism and features

Table-lift system

As containers with mixed and defoamed materials are fixed on the table, syringes are directly filled by pistons.

Features

- The high filling load of the filling machine makes it suitable for filling highly viscous and thixotropic materials.

- As material containers are fixed on the precisely controlled table, syringes are directly filled through container adapters.

⇒They can be filled efficiently because the pathways of materials are straight and short. - Since no valve is used, the liquid contact parts are structured with extreme simplicity, and filling can be performed to the end of the amounts remaining in containers with little loss.

Case ~High-precision mixing, defoaming, and filling~

Material used: Solder paste, Viscosity: 220Pa·s

Before

The solder paste is highly viscous and easily separates, causing problems such as air bubbles and uneven filling in manual operation.

This can cause poor quality or material clogging.

After

By combining our planetary centrifugal mixer and filling machine, material uniformity and air bubble removal are achieved at the same time.

Precise control enables stable filling with high precision even when handling a small amount of materials.Industries and materials

- Electronic components industry(Thermal grease, silver paste, heat dissipation grease, etc.)

- In-vehicle/automotive industry(Ceramics, solder paste insulating materials, rubber-based adhesives, etc.)

- Dental industry(Composite resins, powder slurries, etc.)

Compatible with a wide range of syringes and barrels

The SJ series is compatible with special syringes, barrels and products from various manufacturers.

Please feel free to contact us.Compatible size SJ-1200 SJ-800 3ml 〇* 〇* 5ml 〇* 〇* 10ml 〇 〇 20ml 〇 〇 30ml 〇 〇 50ml 〇 〇 55ml 〇 〇 70ml 〇 - 2.5oz 〇 〇* 100ml 〇 - 6oz・170ml 〇 - - *Compatible by adding optional parts.

Specifications

Item Description method Manual Filling method Table-lift system Material container Standard containers available(Approx. 300ml or 400ml container) Outer dimensions W315 x D305 x H560 (mm)

(*Not including top syringe clamp part)Weight Approx. 30kg Power supply voltage ー Required air pressure 0.4〜0.7MPa - *Specifications are subject to change without notice.

-

Handling large-capacitybarrels

modelSJ-1200[Automatic model]

CE marking -

For small-capacity syringes

modelSJ-800[Tabletop model]

FreeBrochure Download

Includes product specifications and useful information that help you select a product.

The brochure may also be used with the Ringi system, etc.

Download a brochure from here (free)

* You will be redirected to a page on another domain managed by us.

Introduction Examples

Product Information

- Search by Model

- Search by Throughput and Capacity

- Search by Application

-

Atmospheric Pressure Models

Optimum settings for materials by easy operation

Vacuum Equipped Models

In further pursuit of defoaming

High-spec Models

Realization of high performance with a simple mechanism

Exclusive Models

Diverse types of mixing

with one unit -

Large Capacity

4000ml x 2 cups ~ 7000ml x 2 cups

Medium Capacity

1100ml x 2 cups ~ 2000ml x 2 cups

Small Capacity

~ 400ml x 2 cups

* The above show volumetric capacities. The weight per volume varies depending on the specific gravity of the material.

-

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

Dispersing

Example material: Fluorescent powder + Resin

Crushing

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

Separating

Example material: Adhesive + Colored stone

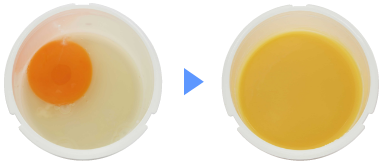

Emulsifying

Example material: Egg + Oil + Vinegar

Search by Keyword

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)