Mixer Introduction Guide

01First, What is Mixing?

“Mixing” is, in a broad sense, the designation of operation to agitate liquids, powders, or granules, and what we call it varies and has various meanings according to application and purpose. Here, terms relating to “mixing” are introduced.

Mixing is performed for various purposes!

Mixing

Refers to operation to agitate liquids, powders, or granules. This term is used for agitation between liquids and between powders, such as for ink toning.

Material: Printing ink

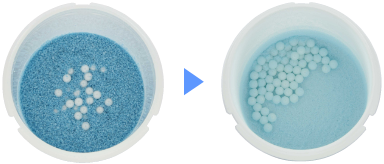

Dispensing

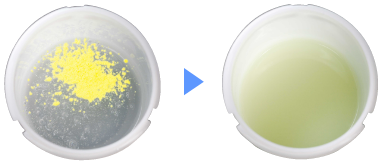

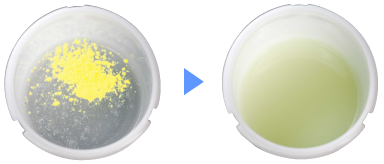

Refers to uniform scattering of particles in solvent so that they are not precipitated or aggregated. This term is used for blending fillers and resins, etc.

Material: Fluorescent powder + Resin

Kneading

Refers to mixing and kneading materials thoroughly. This term is used for mixing hard materials, such as rubber.

Material: Clay

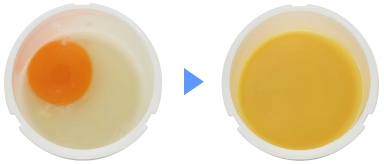

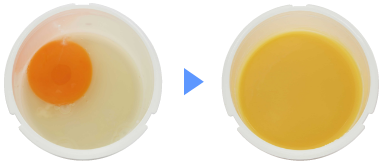

Emulsifying

Refers to a state in which either of the materials that are not mixed by nature, like water and oil, are homogeneously dispersed in the other.

Material: Egg + Oil + Vinegar

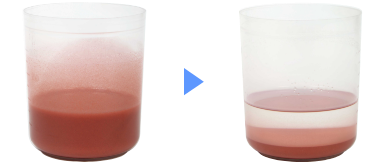

02First, What is Defoaming?

“Defoaming” broadly refers to removal of bubbles (foam) mixed in liquid materials.

There are various defoaming methods, but here, two methods are introduced: “centrifugal defoaming” and “vacuum defoaming.”

Two major techniques for defoaming:

Centrifugal defoaming

Defoaming can be performed by using a planetary centrifugal mixer or the like that increases the effect of pressing materials against container sidewalls in the circumferential direction of revolution, where air bubbles in the materials are separated, and part of the materials is thinly drawn out on the container sidewalls to form a thin film.

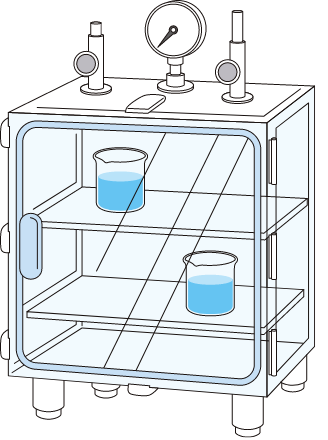

Vacuum defoaming

Defoaming can be performed in a shorter time than being left under atmospheric pressure by using a vacuum chamber or the like that is brought into a vacuum state, where air bubbles in the materials expand in volume, increasing buoyancy.

03Points to note when selecting a mixer

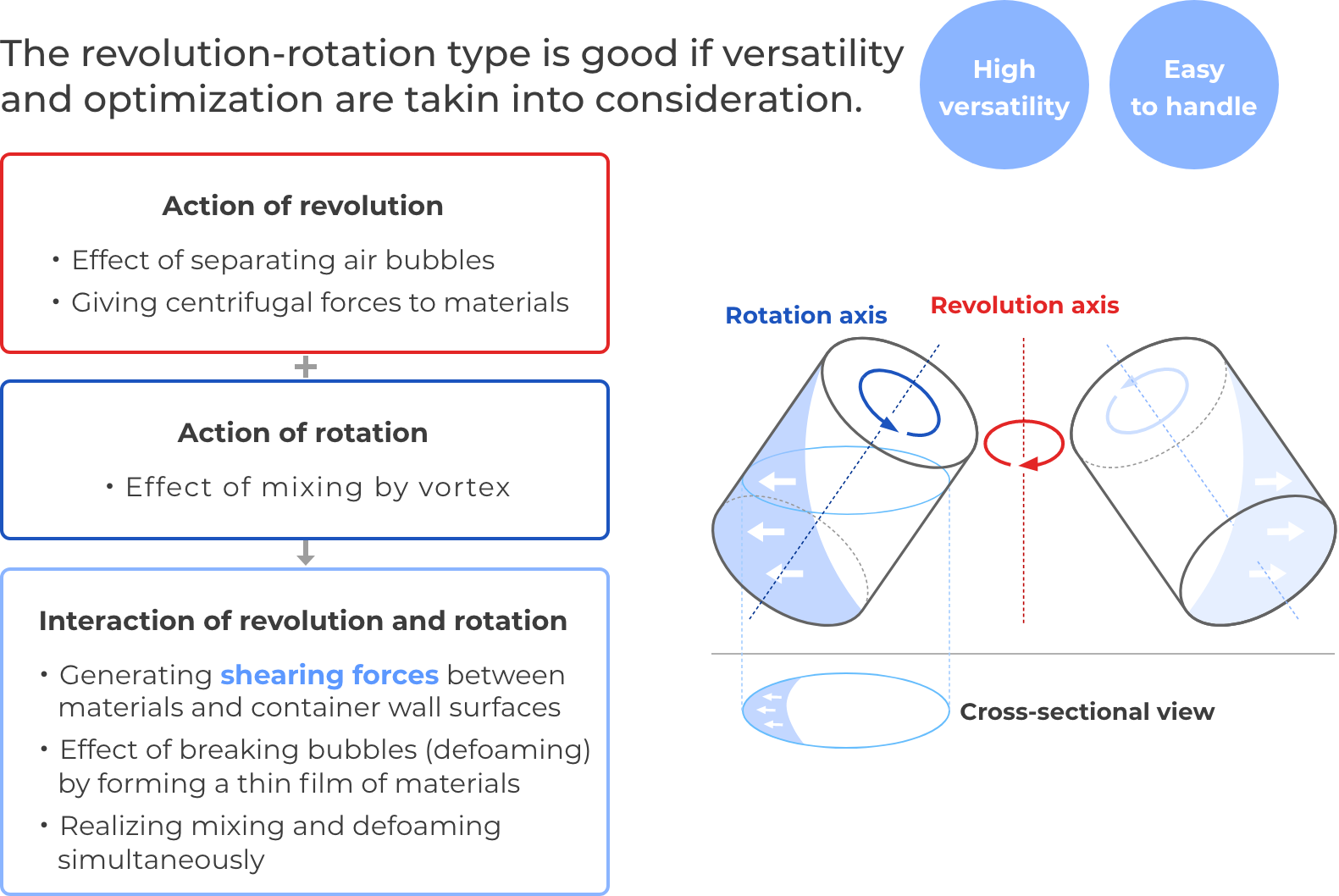

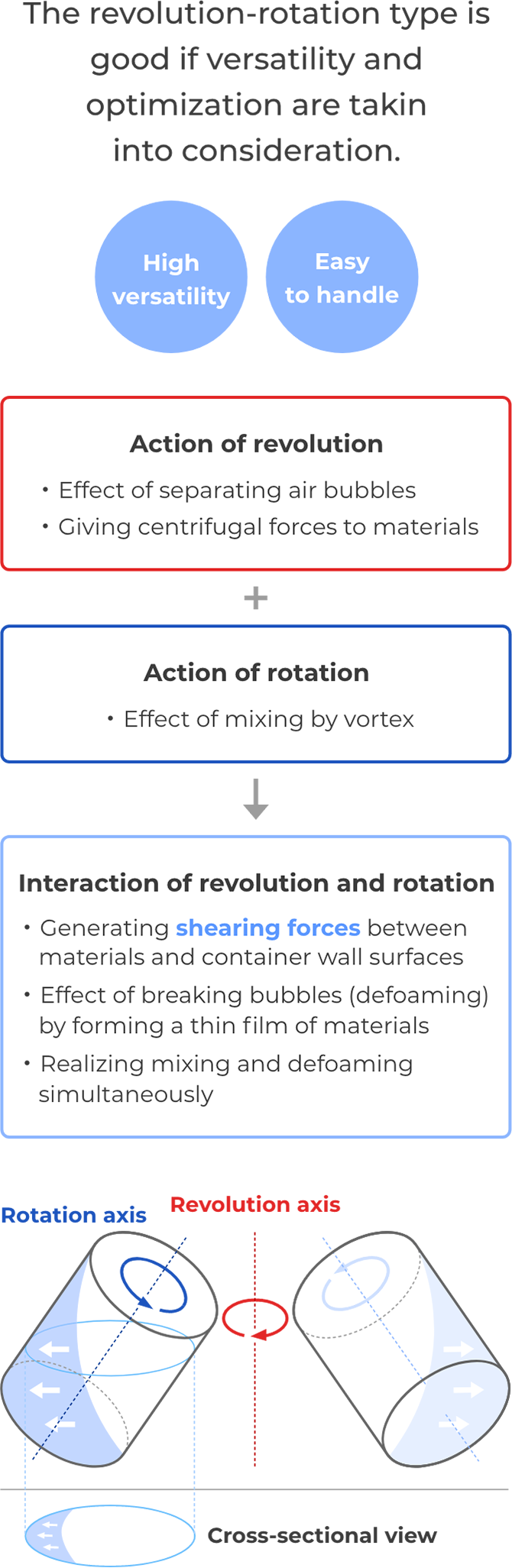

Mixing methods vary with mixers. They should be selected according to application. "For those who are unsure which machine to choose," the recommended first machine is the revolution-rotation type that can process a wide variety of materials. Mixing and defoaming can be processed simultaneously in a short time, and also for changing materials, the containers just need to be replaced. It is an easy method to use even for those unfamiliar with handling.

Features of other methods

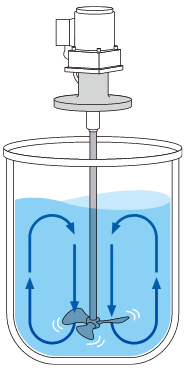

Propeller type

Features and advantages

- Mixing takes time.

- There is a loss of materials because the propeller and materials come in contact with each other.

- Materials are damaged because the composition is sheared by the propeller.

- Precise mixing cannot be performed.

- There is a need for cleaning.

- Defoaming cannot be performed.

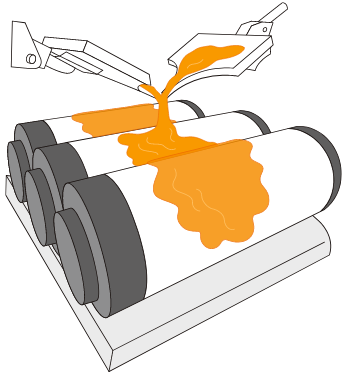

3-roll type

Features and disadvantages

- Mixing takes time.

- There is a loss of materials because the rolls and materials come in contact with each other.

- Not suitable for low-viscosity materials.

- There is a need for cleaning.

- There is a risk of being entangled in the rollers.

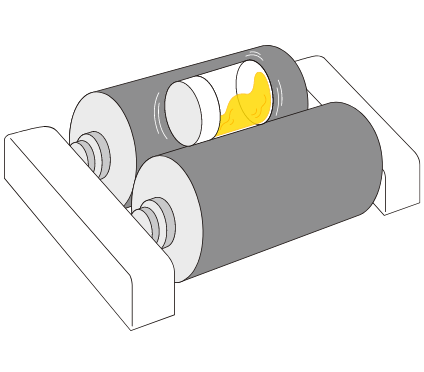

Roller type

Features and disadvantages

- Mixing takes time.

- There is a possibility that air bubbles may be generated during mixing and materials may be separated or precipitated during the preparation process.

- Not suitable for high-viscosity materials.

More Details about the Planetary Centrifugal Mixer

04 Pick up the mixer you are looking for!

Search by throughput and capacity

Search by application Mixing

Mixing

Example material: Printing ink

Defoaming

Example material: High-viscosity adhesive

Dispersing

Example material: Fluorescent powder + Resin

Crushing

Example material: Colored stone (zirconia balls used)

Kneading

Example material: Clay

Separating

Example material: Adhesive + Colored stone

Emulsifying

Example material: Egg + Oil + Vinegar

We also conduct mixing demonstrations and consultations.

Inquiry / Brochure Request

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)